Filter fans for electrical cabinets and enclosures

Heat dissipation from electrical cabinets or enclosures is an important factor to consider when designing an electrical panel, and the most suitable type of ventilation for this purpose is often debated among technical experts.

The importance of the heat dissipation

Heat dissipation from electrical cabinets or enclosures is an important factor to consider when designing an electrical panel, and the most suitable type of ventilation for this purpose is often debated among technical experts.

What is clear is that you need to determine the required air flow rate, based primarily on the type of electrical enclosure, the ambient conditions in which it is located, and of course the heat generated within the enclosure.

Fan installation

There are many theories as well as contrasting opinions on the type of airflow required to create the appropriate heat dissipation. This leads to the conclusion that there is not a perfect solution to all airflow requirements and that it would therefore be better to consider each application individually.

Natural ventilation, forced ventilation, parallel or in-line installation are some of the cooling applications and installation methods used.

Filter fan installation

There are many views as to which configuration of airflow system is best in order to achieve the appropriate heat dissipation, and inevitably, there is no one single perfect airflow solution that meets all heat dissipation situations, and so it’s better to consider each application individually.

Natural ventilation, forced ventilation, parallel or in-line installations are some of the ventilation and installation methods used.

Examples of different configurations

- Natural ventilation with exhaust filter: This is particularly suitable when the temperature inside the electrical cabinet is not particularly high, since it has a limited cooling capability.

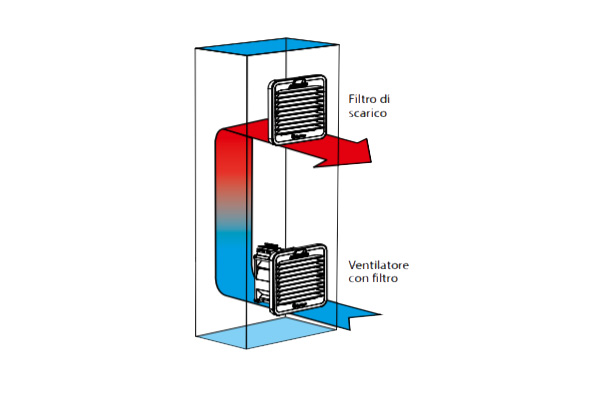

- Standard filter fan unit in the bottom part and exhaust filter in the top part of the enclosure:

Forced ventilation, with air pulled from outside into the enclosure, can be the right solution for more efficient cooling of electrical cabinets that contain significant sources of heat generation.

Configurations

The above configurations are suitable in circumstances where the outside temperature is lower than the temperature inside the electrical cabinet, and in the case of a fan unit, where a more “targeted” airflow is required.

The Finder Type 7F.20 filter fans, available in a range of different sizes, are ideal for these types of applications.

Reverse ventilation unit placed in the top part of the enclosure and filter in the bottom part

In this configuration, airflow is drawn from the inside of the enclosure and expelled to the outside.

Unlike with the previous example, this configuration is particularly suited for cooling the inside of the cabinet in warmer settings. In this case the most suitable products are the Finder Type 7F.21 fans, with reverse airflow. These are available in a range of different sizes according to the required airflow, which in turn depends upon the heat needed to be dissipated.

In both cases, whether with a standard airflow or reverse airflow, it’s important to use an exhaust or inlet filter, as pressure differentials created by these airflows can cause dust and contaminants to move around or enter into the cabinet. It’s common knowledge that dust or contaminants contribute to the reduction of the working life of components, which can lead to early equipment failure.

However, with the proper checking and maintenance of the filter mat, filters are the most efficient way of preventing this type of problem.

Nowadays these operations are even simpler because the filter mat can be easily and safely replaced or cleaned by simply opening the external/front grille, without having to dismantle the entire fan unit.

Finder Filter Fans with either standard or reverse airflow

Available in various sizes, complete with filter, and in either standard or reverse airflow versions, the Finder 7F Series range of filter fans for electrical cabinets and enclosures has recently been updated, and has been given a design make-over by Fossati-Minelli.

All the products in the range boast:

– very low noise rating

– easily replaceable inner filter mat

– minimum external space

All the products for ventilating electrical cabinets and enclosures designed by Finder are UL certified and conform to other technical standards, depending on Type, such as: EC, EAC and cURus.

Filter working life and material

The filter mats are made of an innovative synthetic fibre which is resistant to temperatures up to +100° C and is self-extinguishing to Class F1 (DIN 53438). Installation is simply a matter of clipping the parts together, being optimized for 1.5 mm thick metal.

Panel thicknesses between 1 and 2.5 mm can also be accommodated. For added security we also recommend using the screws supplied in the box.

Models and sizes

Finder’s 7F Series range of fans for electrical cabinets includes models of various sizes, from size 1 to size 5.

Types 7F.20 and Type 7F.50 are standard airflow fans, while Type 7F.21 are models with reverse airflow.

The larger size fans

To complete its range of filter fans, Finder has recently launched larger sized models: Size 4 (250 x 250 mm) and size 5 (320 × 320 mm).

The new Types 7F.20.x.xxx.4250 and 7F.20.8.xxx.4400 size 4 filter fans, with flow rates of 250 and 400 m3/h respectively, feature easily replaceable filter mats as with the smaller-sized versions. They also flow at a significantly higher air volume than other size 4 filter fans on the market.

Technical Specifications

There will be differences (depending on type) in terms of nominal voltage, air volume and other characteristics –so the full technical specifications should be consulted before deciding which filter fan to purchase.

- Nominal voltage: 24 V DC, 120 or 230 V AC (50/60 Hz)

- Air volume (24…400)m3 /h (free flow)

- Air volume (14…270)m3 /h (with exhaust filter installed in the electrical cabinet/enclosure)

- Push-in connections

- Reverse flow filter fan (code 7F.21)

- Protection category: IP54/Type 12

- Sizes from 92 mm up to 250 mm